Phone: +49 (0) 6152 - 98 01 - 5

Bourdon Tube Pressure Gauges: Function, Application, and Working Principle of Pressure Measuring Instruments

Table of Contents:

Functionality of Bourdon Tube Pressure Gauges Construction of Bourdon Tube Pressure Gauges Measurement Ranges and Accuracy Material and Variants Advantages and Disadvantages Applications

Functionality of Bourdon Tube Pressure Gauges

Bourdon tube pressure gauges are precise instruments designed for measuring pressure in gases, vapors, and liquids. They operate on the principle of elastic deformation of a Bourdon tube. When pressure is applied, the Bourdon tube either expands or contracts, and this movement is translated into a pressure indication on the gauge's scale.

Construction of Bourdon Tube Pressure Gauges

A Bourdon tube pressure gauge comprises several key components:

- Bourdon Tube: The core component, consisting of a curved tube. Under pressure, the tube expands or contracts, initiating movement.

- Socket: Connects the gauge to the pressure source.

- Closure: Seals one end of the Bourdon tube.

- Casing: Provides protection to internal components.

- Gear Segment and Movement Gear: Transmit the tube's movement to the gauge's needle for pressure display.

Measurement Ranges and Accuracy of Bourdon Tube Pressure Gauges

- Wide Measurement Range: Bourdon tube gauges are available in a broad range, from millibars to several thousand bars.

- Variable Accuracy: Depending on the model and application requirements, accuracy ranges between ± 0.1% and ± 2.5% of the full-scale value.

- Consideration of Environmental Factors: Accuracy can be affected by ambient temperature, pressure fluctuations, and other environmental conditions. Regular calibration and maintenance are essential for optimal accuracy.

Material and Variants of Bourdon Tube Pressure Gauges

The choice of material depends on the application:

- Standard Construction: Typically made of non-ferrous metals for less aggressive media.

- For Aggressive Media: Utilizes high-quality materials like stainless steel (e.g., 1.4571, 1.4404) or Monel for enhanced resistance.

Temperature Considerations for Bourdon Tube Pressure Gauges

- Ambient Temperature: Operating range typically between -40°C and +80°C.

- Medium Temperature:

- Non-Ferrous Metal Gauges: Up to +100°C.

- UNI Gauges (e.g., Stainless Steel 316L): Up to +150°C.

Advantages and Disadvantages of Bourdon Tube Pressure Gauges

Advantages:

- High Precision and Reliability: Offer accurate and reliable pressure measurements across various industries.

- Versatile Applications: Suitable for diverse applications across industries, including chemical, petrochemical, and power generation.

- Robust Construction: Durable design ensures longevity and resilience in challenging environments.

- Long Lifespan: Quality materials and manufacturing result in extended service life.

- Low Maintenance: Typically require minimal maintenance, reducing operational costs over time.

Disadvantages:

- Sensitivity to Environmental Factors: Susceptible to accuracy issues if not adequately protected from extreme environmental conditions.

- Not Suitable for Extremely Precise Measurements without Calibration: Regular calibration and maintenance are necessary for highly precise applications.

- Relatively Higher Initial Costs: Initial investment may be higher compared to other pressure measurement devices, impacting budget considerations.

Applications of Bourdon Tube Pressure Gauges

Bourdon tube pressure gauges find extensive applications across various industries, including:

- Chemical Industry

- Petrochemical Industry

- Power Generation

- Mechanical Engineering

- Food Industry

- Pharmaceutical Industry

- Environmental Engineering

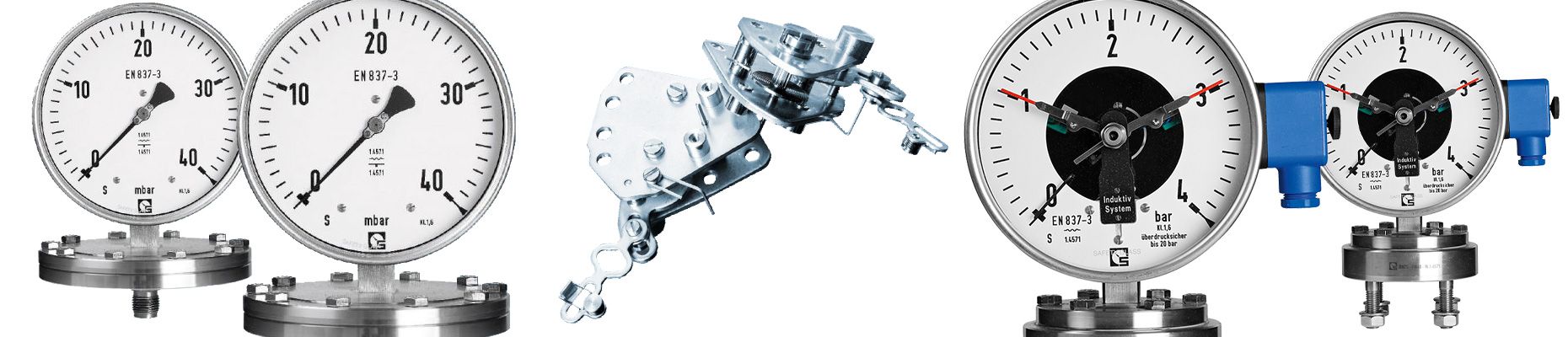

Explore Our Range of Bourdon Tube Gauges

Discover our wide selection of Bourdon tube gauges, designed to meet a variety of industrial applications. Our products offer high reliability and precision, complying with EN 837-1 standards. Available in different sizes and materials, our gauges are tailored to meet your specific measurement requirements.

Bourdon Tube Gauge R 40, R 50, R 63

- Diameter 40 / 50 / 63 mm

- EN 837-1

- Class 1,6 resp. 2,5

- Bourdon tube and connection made of brass

- Plastic window

- Case made of steel

- Threading 1/4″ BSP resp. 1/8″ BSP ( for diameter 40 mm)

Bourdon Tube Gauge RU 40

- Diameter 40 mm

- EN 837-1

- Class 1,6

- Bourdon tube and connection made of stainless steel

- Window made of polycarbonate

- Bayonet lock case made of stainless steel

- Threading 1/8″ BSP or special thread on request

Bourdon Tube Gauge RU 50

- Diameter 50 mm

- EN 837-1

- Class 1,6 (> 600 bar class 2,5)

- Bourdon tube and connection made of stainless steel

- Window made of polycarbonate

- Case with crimped-on ring made of stainless steel

- Threading 1/4″ BSP or special thread on request

Bourdon Tube Gauge RU 63

- Diameter 63 mm

- EN 837-1

- Class 1,6

- Bourdon tube and connection made of stainless steel

- Window made of safety glass

- Bayonet lock case made of stainless steel

- Threading 1/4″ BSP or special thread on request

Bourdon Tube Gauge R 100

- Diameter 100 mm

- EN 837-1

- Class 1,0

- Bourdon tube and connection made of brass

- Window made of glass

- Bayonet lock case made of stainless steel

- Threading 1/2″ BSP or special thread on request

Bourdon Tube Gauge RU 100

- Diameter 100 mm

- EN 837-1

- Class 1,0

- Bourdon tube and connection made of stainless steel

- Window made of safety glass

- Bayonet lock case made of stainless steel

- Threading 1/2″ BSP or special thread on request

Bourdon Tube Gauge R 160

- Diameter 160 mm

- EN 837-1

- Class 1,0

- Bourdon tube and connection made of brass

- Window made of glass

- Bayonet lock case made of stainless steel

- Threading 1/2″ BSP or special thread on request

Bourdon Tube Gauge RU 160

- Diameter 160 mm

- EN 837-1

- Class 1,0

- Bourdon tube and connection made of stainless steel

- Window made of safety glass

- Bayonet lock case made of stainless steel

- Threading 1/2″ BSP or special thread on request

Bourdon Tube Gauge R 250

- Diameter 250 mm

- EN 837-1

- Class 1,0

- Bourdon tube and connection made of brass

- Window made out of Glass

- Case made of Aluminum

- Ring made of steel

- Threading 1/2″ BSP or special thread on request

Bourdon Tube Gauge RU 250

- Diameter 250 mm

- EN 837-1

- Class 1,0

- Bourdon tube and connection made of stainless steel

- Window made from Safety Glass

- Bayonet lock case made of stainless steel

- Threading 1/2″ BSP or special thread on request

Bourdon Tube Gauge R 400

- Diameter 400 mm

- Class 1,0

- Bourdon tube and connection made of brass

- Window made of acrylic glass

- Case + Ring made of aluminium

- Threading 1/2″ BSP or special thread on request