Phone: +49 (0) 6152 - 98 01 - 5

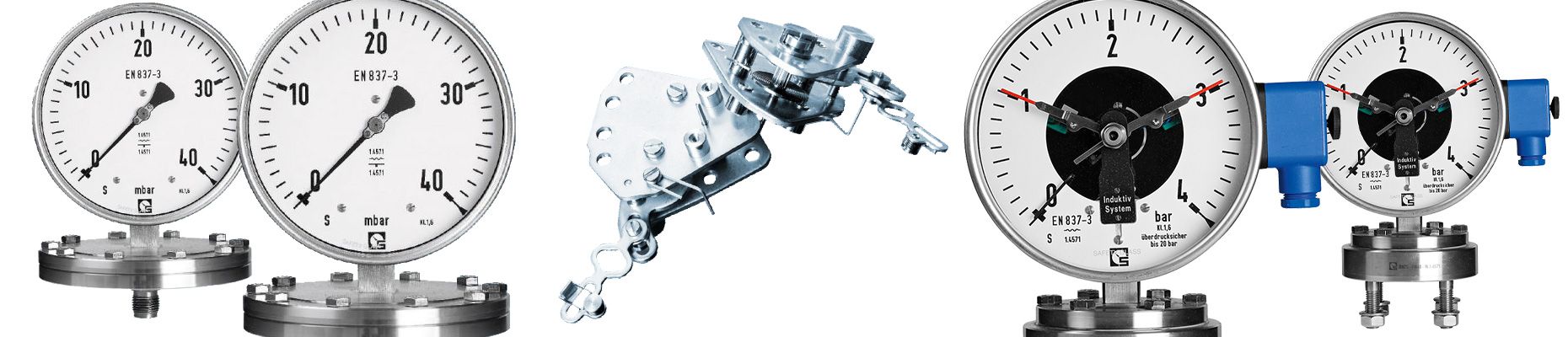

Differential pressure gauges

Function of a differential pressure gauge

The measuring chamber is separated trough a thin, corrugated metal membrane. Pressure will be the applied to both sides and additionally on one side there will be measuring pressure applied. Through a pass through bellow the bending of the membrane will be transferred to the movement. On the opposite side there will be a compensation to balance out the applied forces.

Application purpose

Differential pressure gauges are especially well suited to measure gaseous and fluid mediums that also can be aggressive. The display accuracy is 1,6% or 2,5 % from the upper range level.

Ambient / media temperature

The admissible ambient temperature of the pressure gauge is between -20°C and +60°C. The maximum temperature of the medium shouldn’t be higher than 100°C.

Differential Pressure Gauge DKU 100

- Diameter 100 mm

- Class 1,6

- Diaphragm, measuring chamber and connection made of stainless steel

- Static pressure max. 25 bar

- Bayonet lock case made of stainless steel

- Threading 2 x 1/2″ BSP or special threading on request

Differential Pressure Gauge DKU 160

- Diameter 160 mm

- Class 1,6

- Diaphragm, measuring chamber and connection made of stainless steel

- Static pressure max. 25 bar

- Bayonet lock case made of stainless steel

- Threading 2 x 1/2″ BSP or special threading on request

Differential Pressure Gauge DGU 100

- Diameter 100 mm

- For low pressure ranges <600 mbar

- Class 1,6

- Diaphragm, measuring chamber and connection made of stainless steel

- Static pressure max. 10 bar

- Bayonet lock case made of stainless steel

- Threading 2 x 1/2″ BSP or special threading on request

Differential Pressure Gauge DGU 160

- Diameter 160 mm

- For low pressure ranges <600 mbar

- Class 1,6

- Diaphragm, measuring chamber and connection made of stainless steel

- Static pressure max. 10 bar

- Bayonet lock case made of stainless steel

- Threading 2 x 1/2″ BSP or special threading on request